Machine Design and Vehicles Department

Short description of works carried out by KMiP Department staff

| Subject | Type of works |

| Expert jobs and consulting | Consulting and troubleshooting of machines and systems. |

| Machine design analysis, FEM analysis | Analysis and optimisation of machines design with the use of finite element method (FEM). |

| Design of machines and systems | Design of atypical machines and systems (including test rigs, quality testers etc). Manufacturing of designed prototypes and systems and their implementation. Design of power transmission systems. |

| Structural steelwork design and hull modifications | Design of prototype steel constructions utilized for off-shore processing of crude oil. Analysis of stress and strain in existing steel constructions utilized at sea. |

| Bearing engineering | Bearings investigations (in real life and on laboratory tests rigs). Design and modernization of bearing systems, especially with hydrodynamic thrust and journal bearings. Design of unconventional bearings. Assessment of bearing systems condition, consulting in the areas of failure analysis, bearing design and manufacturing technology. Bearings manufacturing in cooperation with specialised firms. Engineering supervision over: manufacturing, assembly and commissioning. |

| Friction, wear and lubrication | Analysis and selection of bearing materials for unconventional bearing systems (e. g. water lubricated or dry). |

| Computational assessment of pipelines condition | Computation of stresses caused by deformation of pipelines or its corrosion defects (using finite element method and also according to ASME and DNV standards). |

Short descriptions of selected projects

Expert jobs and consulting.

Consulting and troubleshooting of machines and systems.

(More information: Prof. Michał Wasilczuk, PhD. Eng.)

.jpg)

.jpg)

.jpg)

(More information: Prof. Michał Wasilczuk, PhD. Eng.)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(More information: PhD. Eng. Jacek Łubiński)

.jpg)

.jpg)

.jpg)

.jpg)

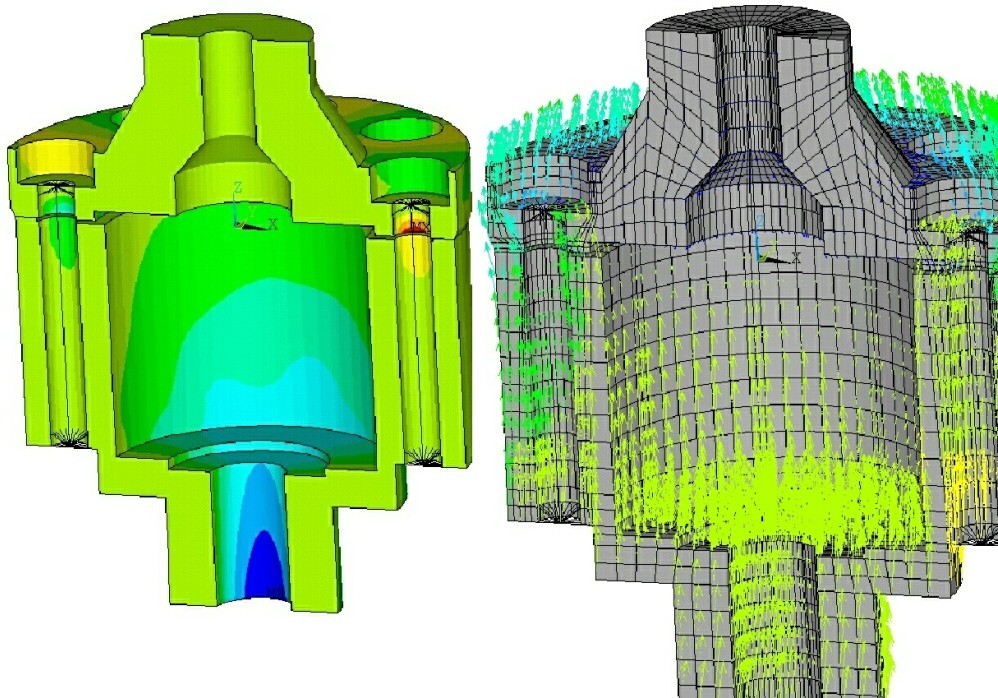

Machine design analysis, FEM analysis

Analysis and optimisation of machines design with the use of finite element method (FEM).

(More information: PhD. Eng. Jacek Łubiński)

.jpg)

(More information: PhD. Eng. Artur Olszewski)

.jpg)

(More information: PhD. Eng. Rafał Gawarkiewicz)

(More information about details of prepared simulations: PhD. Eng. Rafał Gawarkiewicz)

.jpg)

.jpg)

(More information about details of prepared simulations: PhD. Eng. Rafał Gawarkiewicz)

Simulation of contact spring (for EATON Gdańsk - now DELPHI AUTOMOTIVE SYSTEMS).

Simulation of the manufacturing process of a spring in a car light switch was carried out with the use of ANSYS FEM code. Computation took into account elasticity effects. The deflection of the switch spring during manufacturing process has an influence on the force exerted by the spring in the switch, as well as tolerances of the spring. Influence of manufacturing tolerances and material properties variation on the force exerted by the spring was investigated. Results show, that variation of material properties has lower influence on the spring constant than working tolerances. As a conclusion a spring deflection in manufacturing process and manufacturing tolerances required to obtain a desired spring characteristic were specified.

Projektowanie maszyn i urządzeń

(More information: PhD. Eng. Artur Olszewski)

.jpg)

(More information: PhD. Eng. Paweł Romanowski, Prof. Assistant)

.jpg)

Design of steel constructions

Design of PG-1 jacket - element of oil deposit system managing on Baltic Sea (for PETROBALTIC Oil and Gas Exploration - Production Co. Ltd.)

Various designs of jacket rig were thoroughly analysed in terms of stress and stability in various sea conditions. Analysis took into account loading by dead weight, buoyancy, sea waves, sea currents and wind. Entire task was carried out in cooperation with Mechanics and Strength of Materials Department of the Faculty of Mechanical Engineering of Gdańsk University of Technology. Recommendations of API RP2A for permanent naval constructions were used. On the basis of analysis results main structural welded components were designed. After approval by PRS (Polish Register of Shipping), Marine Board and Mining Board the platform was build and put into operation in 1998

Hull modification designs for drilling rigs "Petrobaltic" and "Baltic Beta" (for PETROBALTIC Oil and Gas Exploration - Production Co. Ltd.)

Several designs of hull modifications for oil rigs were made between years 1997 and 2004. The designs included: slot walls reinforcement on Petrobaltic rig, deck reinforcement on "Baltic Beta" rig for the installation of sea water deaerator column and later for a natural gas compression system. The latter design work was carried out in the year 2002, and the system was put into operation in 2003. Strength analysis with the use of finite element method was carried out in all the above mentioned designs. Designs were also revised and approved by PRS (Polish Register of Shipping).

(More information: PhD. Eng. Jacek Łubiński)

.jpg)

Bearing engineering - friction, wear and lubrication

Modernization of bearings of water turbines of Myczkowce Power Plant. Design of water lubricated guide bearing (for Pumped Storage Power Plants Company and Zakład Remontowy Energetyki (ZRE)).

Possibility of application of water lubricated journal bearings in Kaplan-type hydro turbines was analysed. For this purpose calculations of dynamic behaviour of rotating shaft of hydro generator were carried out. The finite element method (FEM) was applied. The shaft model took into account: inaccuracies of shaft alignment, unbalance, lateral hydraulic thrust on turbine rotor. Bearings were modeled as elastic elements with nonlinear characteristics computed separately with the aid of a specialised computer program. Results of analysis allowed for evaluation of acceptable level of unbalance, alignment errors and hydraulic thrust on turbine rotor in case of application of water lubricated bearing. Other requirements were specified. Additional design changes, which lead to easier turbine assembly and improved ecological safety were suggested. At the next stage, water lubricated bearing was designed together with an appropriate manufacturing process. Bearing manufacturing and assembly was supervised.

Project of modernization of thrust bearing of hydro turbines of Dychów Water Power Plant (different parts for Energoprojekt Warsaw, Pumped Storage Power Plants Company, Voith Siemens Austria and ZRE Gdańsk). More information: Prof. Michał Wasilczuk, PhD. Eng.

Data from bearing operation was analyzed. In order to assess the possibility of bearing operation in new operating conditions calculations were carried out. Calculations showed, that there was a need of improved load distribution among bearing pads and of housing design modification. A modified thrust bearing was designed, in addition hydrostatic jacking system was introduced. Bearing manufacturing was supervised. Much lower variation of bearing pads temperatures in the modernized bearing confirmed the improved load distribution.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(More information: Prof. Michał Wasilczuk, PhD. Eng.

.jpg)

.jpg)

.jpg)

.jpg)

(More information: Prof. Michał Wasilczuk, PhD. Eng.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(More information: PhD. Eng. Artur Olszewski)

.jpg)

(More information: PhD. Eng. Artur Olszewski)

.jpg)

(More information: PhD. Eng. Artur Olszewski)

.jpg)

(More information: PhD. Eng. Artur Olszewski)

.jpg)

Design and introduction into industrial use of anti-vibrational Y-type hydrodynamic journal bearing which is designed especially for steam turbines (for ALSTOM Power).

Completely new design of hydrodynamic Y-type journal bearing was devised and introduced. That bearing has better anti-vibrational properties than classical multi lobe journal bearings. The Y-bearing was patented. Several Y-type journal bearings were introduced in 78-200 MW steam turbines.

Modernization of 150 MW generator bearings (for ABB Generation Vasteras - Sweden).

An original design of journal bearings with a spherical self aligning housing was elaborated and implemented. Steel surface sliding on PTFE provides minimum friction coefficient between bearing liner and housing, which improves alignment of journal and bearing bush during operation.

Design of anti – vibrational bearings for high-speed transmissions (for MAAG, ABB>Marine).

Design of anti-vibrational bearings with hydrodynamic dam for high-speed geared transmission units manufactured by ABB Marine was elaborated.

Design of modernized bearings of rolling stand (for Ironworks Częstochowa S.A).

Design of modernized bearings of rolling stand was elaborated. Bearings durability was increased. A system of changeable bearing liners was introduced, which allows to cut downtime.

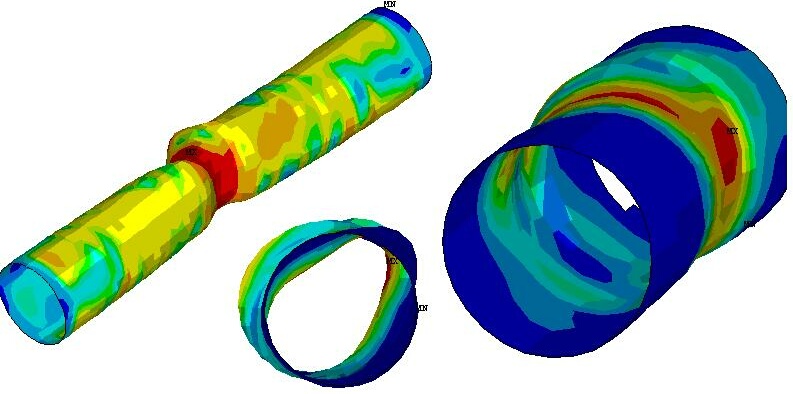

Computational assessment of pipelines condition

A method of computing stress in pipeline walls, caused by deformation or corrosion defects on the basis of measurements carried out by a special inspection gauge (for CDRiA Pipeline Services)

With the use of Flugge thin-shell theory, a method was developed for computing stresses in pipeline walls on the basis of data on its deformations acquired by a special inspection gauge. Analysis in linear range took into account: inspection gauge accuracy and pressure inside pipeline. On the basis of the above-mentioned method, a computer code was developed, which was later introduced into regular use by a main Polish pipeline operator.